MTS Applications // Use Cases

Mobile Technical Shelters (MTS)

Our product provides a comprehensive solution for understanding our user's Technical Data Package (TDP) requirements and applications, enabling us to tailor the Calibration/Metrology Shelter, Diagnostic Shelter, or Maintenance Shelter packages to meet our customers' specific needs. Customers can expect a customized solution that effectively addresses their unique requirements and ensures optimal performance.

Mobile Technical Shelters serve as the perfect solution for your mobile Calibration/Metrology workload to include: electrical, electronic, temperature, pressure, physical/mechanical and dimensional Test Measurement and Diagnostic Equipment (TMDE).

Contact Syncro

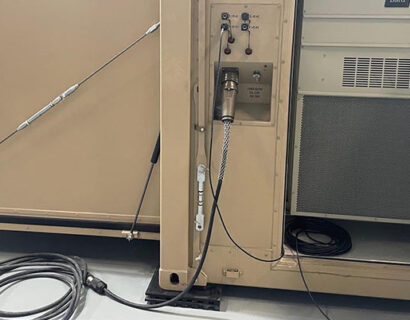

Mobile Technical Shelters are an integral tool for military diagnostic, analytical, test and measurement applications. The MTS system offers an adaptable solution for testing digital and analog electronic hardware and software across a range of weapons and communications platforms. Its mobile, secure, and modular design makes it easy to transport and set up in different locations. Its comprehensive capabilities ensure the reliability and functionality of electronic components in various military applications.

Contact Syncro

The Mobile Technical Shelter for maintenance offers a versatile solution with its 24×20 designable space. The MTS can be configured to suit various needs, such as an Armament Repair Shop, Power Plant, Powertrain, Structural (Airframe), Pneudraulics (Hydraulics), and Avionics/Electrical. It provides a reliable and efficient workspace for maintenance tasks, ensuring optimal functionality and convenience.

Contact Syncro

SYNCRO Design and Configuration Support

The Scope & Solution

SYNCRO’s Scope to Solution process begins with a thorough understanding of our client’s intrinsic requirements and parameters. SYNCRO Corporation has on staff technical Subject Matter Experts with 30 + years of experience in the calibration and metrology field. This experience includes the design and configuration of lab spaces, equipment selection to meet the needs of broad scope calibration requirements, and application-specific requirements related to particular end item applications ranging from Aviation and Missile to Ground Vehicle support.

- Environmentally Controlled 18°C-23°C (64°F-74°F) based on your requirements.

- Fully Customizable based on end user requirements.

- Turnkey Design for customers requiring an on-site calibration laboratory.

Potential Interior Layout:

- Torque wrenches from 5 in lbs to 4,000 ft lbs

- Torque Multipliers up to 20,000 ft lbs.

- Pneumatic gauges up to 10,000 psi.

- Length validation to 24” with incremental ability .0001”

- Pressure standards

- Torque standards

- Different lab configurations

- Physical/Dimensional standards

- DC/Low standards

- Frequency standards

- Microwave/RF standards

- Administrative set-up for production control + calibration lab supervision